Site Investigation Engineer

The deadline for applications is 26/02/2026

Site Investigation Engineer

Location: Nottingham (with site work across the UK)

Contract: Full-time, Permanent

About the role

At Bridgeway, our Site Investigation Engineers are right at the heart of how safe, reliable infrastructure gets built. This is a hands-on role for someone who enjoys being out on site, solving problems, and working as part of a highly skilled team delivering complex ground investigations, particularly within the rail environment.

Reporting to the Principal Engineer / Technical Manager / Project Manager, you’ll play a key role in planning, supervising and delivering ground investigation works from start to finish, ensuring everything is done safely, compliantly, and to a high technical standard.

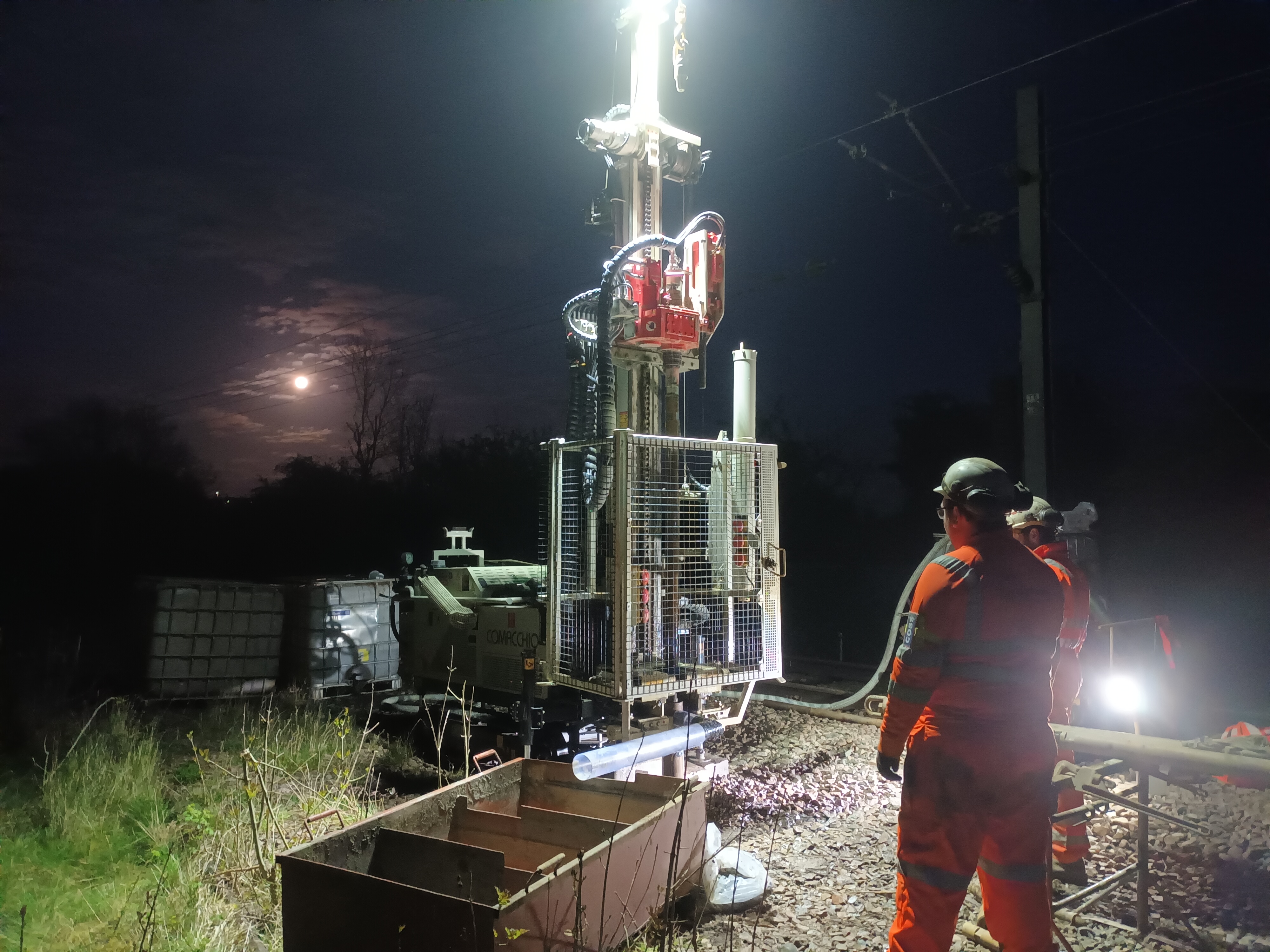

We specialise in rail environments, where investigations often take place at night, on weekends, and in complex conditions. It’s challenging work, but incredibly rewarding.

If you enjoy responsibility, variety, and being trusted to get things done properly - this role is for you.

What you’ll be doing

• Planning and supervising ground investigations, including drilling, sampling and in-situ testing

• Preparing and reviewing method statements and risk assessments

• Ensuring compliance with CDM Regulations, client specifications, and industry standards

• Logging soil and rock in line with BS 5930 and BS EN ISO 14688/14689

• Applying your knowledge of drilling techniques and site investigation equipment

• Installing and monitoring instrumentation such as vibrating wire piezometers, inclinometers, and ground gas & groundwater monitoring

• Liaising with clients, contractors and local authorities to keep projects running smoothly

• Maintaining accurate site records and supporting data analysis and reporting

• Supporting and mentoring graduate engineers on site, sharing knowledge and best practice

What we’re looking for

• Degree in Geology, Physical Geography, Applied Geoscience or a related discipline

• Some industry experience in site/ground investigation

• Good working knowledge of UK Specification for Ground Investigation, EC7, and BS 5930

• Full UK manual driving licence

• A proactive, safety-focused mindset and strong attention to detail

Why Bridgeway?

We’re not a “tick-box” consultancy. We’re known for doing things properly especially in challenging rail environments where standards matter and conditions aren’t always easy.

In return for your commitment, we offer:

• A competitive salary and benefits package

• Exposure to a wide range of complex rail and infrastructure projects

• Clear progression pathways - whether you want to grow technically or move into project management

• Funded training, competencies, and professional development

• A supportive culture where people are trusted, developed, and backed

This is an exciting opportunity to build a long-term career with one of the UK’s leading infrastructure and rail site investigation specialists.